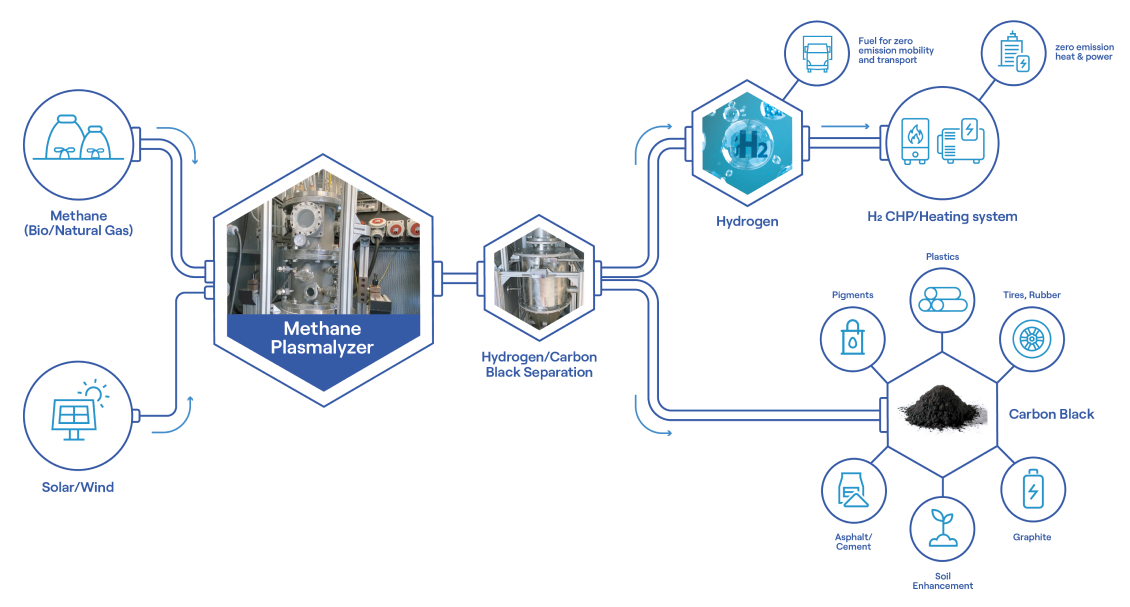

Austria's first hydrogen production plant for the electrolysis of methane in Austria is commissioned in Krift near Kremsmünster. With this promising climate technology, methane (natural gas) will be split into hydrogen and high-purity solid carbon using solar energy, without CO2 emissions. This environmentally friendly energy and raw material innovation provides not only storable and climate-neutral hydrogen, but also the currently scarce raw material "solid carbon" for agriculture and various industrial applications.

The RAG energy valley in Krift near Kremsmünster in Upper Austria is the first with a 100% green energy supply, no wonder that the innovative climate technology "Methan-Elektrolyse" for a CO2-free green raw material supply was commissioned here.

"Climate protection is one of the main tasks of our generation. Our goals are ambitious: 100% renewable electricity in and from Austria by 2030 and climate neutrality in Austria by 2040 - ten years earlier than in the EU," shared Austrian Mining Minister Magnus Brunner. "To achieve these climate goals, we need investment, innovation and cooperation. We must not focus on just a few technologies, but remain open to technology. With its first demonstration plant in Austria, which uses CO2-free natural gas to produce hydrogen and solid, elemental carbon, RAG is focusing on this technological openness that is so urgently needed. Hydrogen contributes significantly to year-round security of supply - the high-quality carbon produced is also a valuable raw material for agriculture, batteries, computer chips and carbon fibre. A win-win situation for the climate and the locality!"

This innovative climate technology has been developed by the German company Graforce and is being implemented and optimised on an industrial scale by RAG for the first time in Austria.

The hydrogen produced can then be stored seasonally in RAG's energy storage systems, such as the "underground solar storage" in Pilsbach and Gampern, or used as industrial hydrogen. At the RAG H2 Krift cogeneration plant near Kremsmünster, the first 100% hydrogen power plant in Austria, this climate-neutral hydrogen is used to supply the site with electricity and heat. In the coming winters, the energy surplus can also be used to supply up to 800 households with green district heating and green electricity in the Kremsmünster region.

Solid carbon: The miracle material

As a result of intensive agricultural use in recent decades, up to 50% of the carbon in the soil has been lost through erosion or loss of humus. Climate change adds further problems, such as long periods of drought. The use of fixed carbon from methane electrolysis offers great potential for improving soil quality and thus ensuring sustainable agricultural production. Otherwise, there is a risk of massive crop failures in the coming decades and thus a threat to food security. Their results from several greenhouse and field experiments show that carbon improves nutrient availability to plants and their resistance to drought stress. Adding nutrient-rich residues (e.g. compost or manure) can also create valuable fertiliser. The next series of experiments will extend the effect to different soil types and other crops in the light of current and expected climate change. With these promising research results, RAG and RWA (Raiffeisen Ware Austria) now intend to intensify their existing cooperation, particularly in the area of product development.

"In view of the current and upcoming challenges of global change and global warming, the carbon from 'Methan-Elektrolyse' can make a significant contribution to ensuring soil quality and agricultural production," emphasises Markus Puschenreiter from the University of Natural Resources and Life Sciences in Vienna.

In addition, solid carbon is a valuable raw material for the sustainable production of building structures, batteries, computer chips, carbon fibres and carbon-based materials. These are used in many industries such as medical technology, aerospace, sports and leisure or high-tech industries.

Around 120 scientists from Montanuniversität Leoben are currently working in this key research area. As of 2022, the numerous activities in the 25 departments are centrally coordinated in the strategic key research area "Hydrogen and Carbon".

Source: RAG Austria